Summary

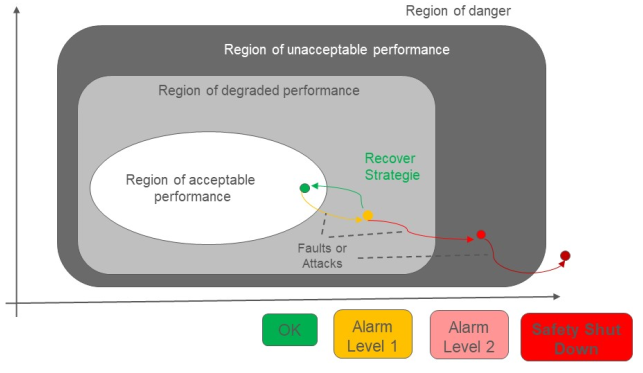

Is a hot rolling mill secured against intentional attacks? Could a re-heating furnace or the accelerated cooling be used for sabotaging the quality of a European steel producer? How can attacks be separated from fault behaviour? AutoSurveillance will provide a solution for detecting anomalies in re-heating furnaces, hot-rolling mills and accelerated cooling, a solution that can announce a threat and in parallel distinguishing between faults and intentional attacks. It focusses on the process-oriented treatment of such occurrences and explicitly not on the IT perspective. To accomplish this task the following paragraph describes the work done during the reporting period.

First, the definition of faults and attacks and their interplay with model uncertainties and disturbance was discussed. And how these can be distinguished in principle from a theoretical point of view. Subsequently, plant-specific details were discussed. Accordingly, a risk assessment of the faults considered, and their financial impact was attempted for

each use case. According to this, physical and data-driven models of the plant and the controls were set up. These models have been extended to include actuator, sensor, and parameter faults models. In addition, models for Denial of Service (DoS), Hidden Attacks have been added. For example, it was possible to show that a DoS attack on the control of the hot strip lines leads to a destabilisation of the control and thus to a strip break. By means of a hidden attack, it is possible to adjust the strip thickness unnoticed. Different methods of detecting faults and attacks were investigated. On the one hand, based approaches such as different observer concepts (Kalman filter, extended Kalman filter and banks of Kalman filter) whose results were evaluated using static decision procedures. On the other hand, data-driven methods were investigated. Here, the focus was on non-linear mapping methods to low dimension and machine learning methods based on auto-encoders. With each of these methods it was possible to detect faults and attacks. The

implementation of the test best for all use cases has been started and preliminary work for the implementation of the concepts at the industrial partners has been accomplished. Initial investigations into reaction strategies to faults and attacks have been carried out, which are tailored to the various use cases. An attempt will be made to develop a uniform concept with the aim of standardising the strategies. In addition, two publications have been made in this project.

Acknowledgement

The project is a multinational effort from partners belonging to different countries (Germany, Italy and Spain), funded by the RFCS program of the EU. Its grant ID number is RFCS – 847202 and the title is “Automatic surveillance of hot rolling area against intentional attacks and faults“.

This EU funded project reaches its first life year. The concept being developed looks oustanding as it promotes process healthy checks from the very low level control devices, without enormous setup.

AI and ML will provide great insights to it.